板式換熱器垢底部位污垢形成的主要成因:

Main causes of fouling formation in fouling at plate bottom of plate heat exchanger:

(1)不銹鋼傳熱板片由機械沖壓而成,不可避免地殘存一定量的表面殘余應力,對于不含鉬元素的不銹鋼薄板,表面殘余應力的消除是很困難的,或者甚至是不可行的。

(1) stainless steel heat transfer plate is composed of a mechanical stamping, inevitably a certain amount of residual surface residual stress, the stainless steel sheet does not contain molybdenum, eliminate the surface residual stress is very difficult, or even impossible.

(2)板片組裝后形成了多縫隙結構,如板片之間的觸點、密封槽底等部位。而縫隙容易造成Cl-的富集,局部富集程度往往遠遠超過了不銹鋼自身抗應力腐蝕的能力。

(2) a multi slit structure is formed after the plate is assembled, such as the contact between the plate and the plate and the bottom of the sealing groove. But the crevice is easy to cause the Cl- enrichment, the local enrichment degree is often far more than the stainless steel itself stress corrosion resistance ability.

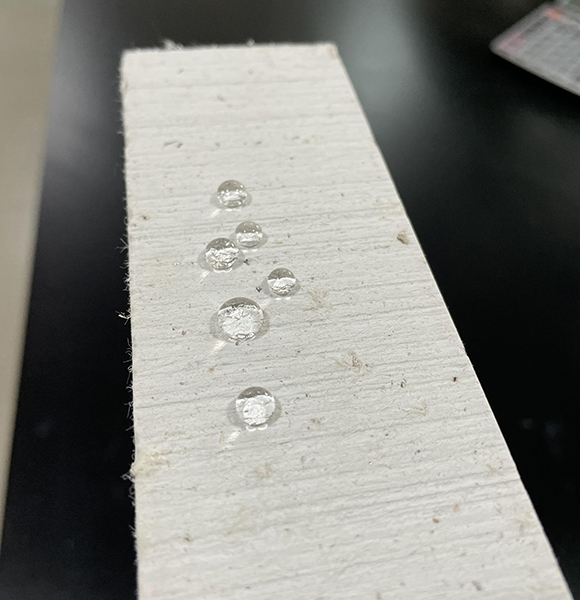

(3)當板片表面的污垢嚴重時,介 中的腐蝕元素(Cl、S 等)可能大量附著于污垢,并在垢底縫隙處富集。

(3) when the dirt on the surface of the plate is serious, the corrosion elements (Cl, S, etc.) in the medium may be heavily attached to the dirt and enriched at the crevice at the bottom of the fouling.

(4)密封槽底中的有害元素往往是粘結劑中的 Cl 因溫度升高溫析出來的。如氯丁 膠系列的粘接劑、壓縮石棉(含有CaCl2),往往在水與蒸汽工況條件下,析出的富集Cl- 與 H+ 形成HCl,使槽底縫隙處發生嚴重的應力腐蝕開裂。

(4) the harmful elements in the bottom of the sealing tank are often the temperature of Cl in the binder. Such as neoprene series of adhesives, compressed asbestos (containing CaCl2), often in the water and steam conditions, precipitation enrichment, Cl- and H+ formation of HCl, so that the gap at the bottom of the groove there is a serious stress corrosion cracking.

![]() 備案號:蘇ICP備17015414號-4 技術支持:

備案號:蘇ICP備17015414號-4 技術支持: